“Substituting wood for conventional buildings materials reduces emissions by 69%.” (Himes & Busby, 2020)

As businesses and individuals, we all have environmental targets to reach and must embrace new ways of working and operating to better the future of our planet. At OFP, this is something to which we are committed as we continue to grow as a responsible organisation.

Over the last two decades, timber has become an increasingly popular building material choice with construction professionals and end users, with its well-recognised sustainable credentials. Wood, even in its most natural form, helps regulate carbon by capturing and storing it, reducing the pollutants in the environment, before it is then used as a building material.

Did you know timber has less embodied carbon than other alternative construction materials, such as steel and cement? In our fight against climate change, it will come as no surprise that the timber frame market is set to rise by more than £150m by 2026, and we only expect this to continue as the years go on.

How do trees compare to concrete and steel?

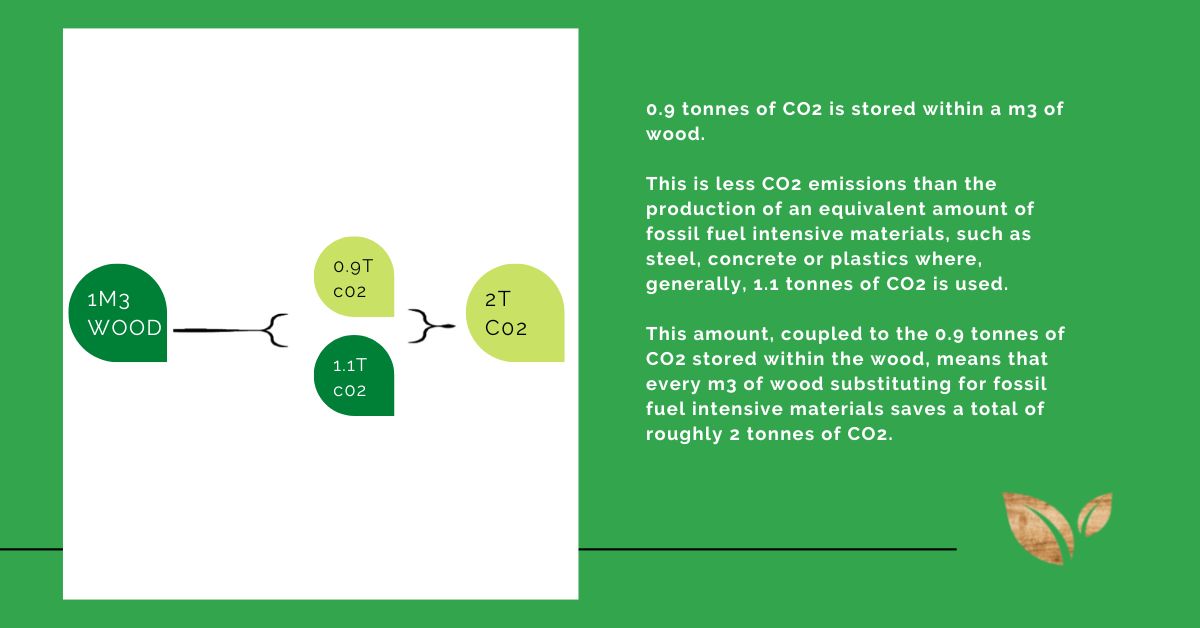

The most significant comparison for these materials is their journey before arriving on-site. Trees, a natural material, absorb and store C02 as they grow whilst fossil fuel-intensive manufactured materials such as steel and concrete emit C02 when produced.

As well as the growing demand to meet environmental and net-zero targets, there is still a huge housing shortage. Our population is ever-increasing and the government and construction industry are under pressure to help tackle this.

So the question remains, how can we build more houses whilst also achieving net-zero? We need a way to build at speed, using sustainable materials while keeping costs and emissions down. This ultimately has to be achieved through a fabric-first approach; like many others, we see timber as the future.

In the words of the Royal Institute of Chartered Surveyors, timber frame delivers “cost-effectiveness, speed and energy efficiency advantages from inception to construction.”

Sustainable beyond its lifetime

Not only is timber sustainable in its production, but once it reaches the end of its lifespan as a building material, it can then be transformed into energy as a biomass or redistributed as chipping for agriculture, for example.

At OFP, this is something we strongly value about the use of timber. We even create pellets from sawdust which we burn in our biomass boilers to heat our offices. Impressed? You can read more about this here.

As the government continues to emphasise the importance of Modern Methods of Construction (MMC) and to achieve environmental targets, we must invest in the right sustainable building solutions.

At OFP, we are committed to responsible construction. Not only are we certified with PEFC and FSC, and STA Gold approved suppliers, but we are also always finding new ways and technologies to reduce waste and improve our efficiency. You can read more about this on our dedicated ESG page.