In 2020 the UK generated around 4.5 million tonnes of waste wood. This wood comes from a number of different sectors, including construction, demolition, manufacturing and wood processing. In addition, households produce huge quantities of waste wood that end up at local Council-run recycling centres and of course, waste pallets by the million and a large quantity of wooden packaging waste are produced right across every sector of the economy. https://communitywoodrecycling.org.uk/

“4.5 million tonnes of waste wood generated”

Wood recycling has undergone a massive boom in the UK, from less than 2% of wood waste in 1990 to more than 80% in 2020, but with many reuse opportunities being missed and around half a million tonnes of wood landfilled every year, the wood recycling story is far from over.

Why Wood and Should You Recycle?

As a business who work solely with wood we work hard to make sure we are doing our very best to recycle as much as we can. Therefore we have implemented our own wood waste management practices and strategies to ensure that we are doing our part. Having a successful wood waste management system in place helps to reduce the impact on the environment, save costs and provides new opportunities for waste wood to be turned into new products which can be used again

Environmental impact

- Recycling prevents more materials from ending up in landfills

- Decrease in Deforestation – The more wood that gets recycled, the less trees need to be cut down which helps preserve and maintain the ecosystem.

Reduction of energy costs

- Decrease in Greenhouse emissions

- Lower Carbon Footprint – Recycling one tonne of wood can save up to 18,000,000 tonnes of energy ( snappyrubbishremovals.co.uk)

- Cost reduction on material processing

Creation of new opportunities

- Recycled wood from construction or other sectors is used to create other other products such as building materials, animal bedding, panel board, feedstock and many more.

- Recycled wood is used to create valuable products that would otherwise use virgin materials to create at a higher cost. Raw materials use a lot more energy to produce.

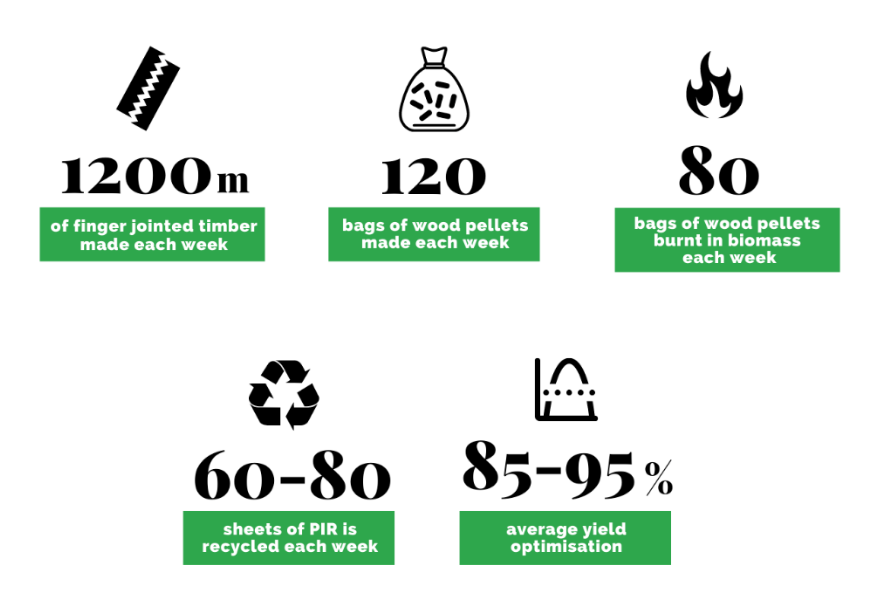

As part of OFP’s waste wood management system we have created 2 methods to help recycle as much of our waste wood as we can:

- Sawdust Pellets: We use sawdust waste to create small ‘pellets’ which we then burn in our biomass boilers. This energy is then used to heat and run our offices and factory

- Finger Jointing: Rather than disposing of offcuts of wood, we join two offcuts together to create a new full sheet which can be used.

Our Recycling Efforts amount to:

We are constantly looking for new ways that we can recycle as well as improve the practices that we have already implemented. For more information on our environmental and sustainable practices, click here.