Background

At OFP, we pride ourselves on manufacturing, supplying and installing the best timber frame solutions for our clients whilst maintaining our commitment to working in the most sustainable ways possible and using Modern Methods of Construction (MMC).

We manufacture various timber frame products such as wall panels, open web floor joists and floor cassettes. In 2020, after high demand from our clients, we launched a new product – roof trusses – and began manufacturing them in our purpose-built factory in Sandwich, Kent.

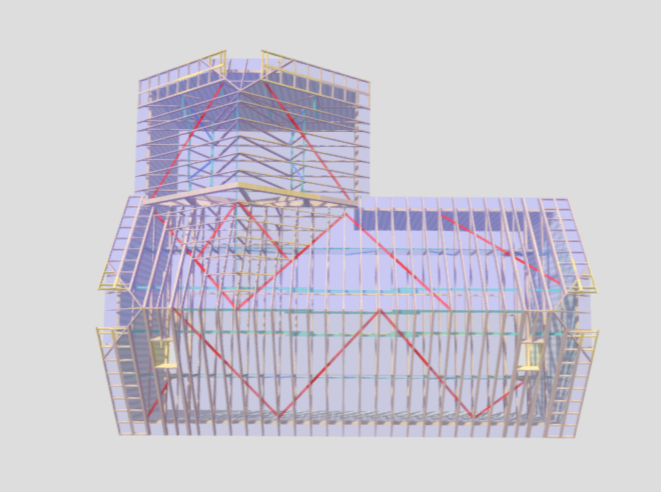

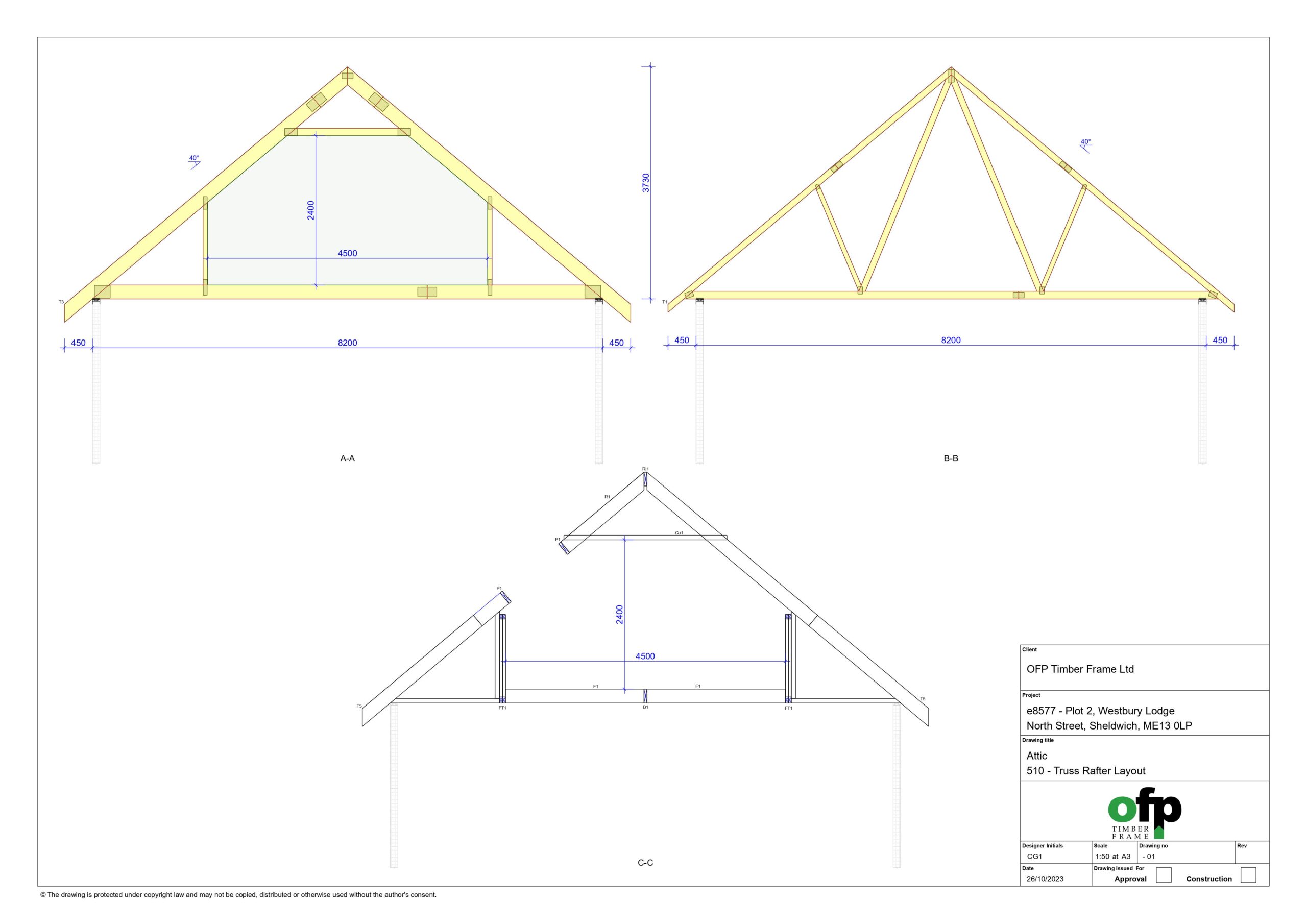

Pictured: OFP Timber Frame – Roof Trusses

In this blog, we will shine a spotlight on our roof truss products, showcasing how we produce them, the options and types we provide to our clients and some key projects where we have manufactured, supplied and installed roof trusses.

What are the different types and styles of roof trusses?

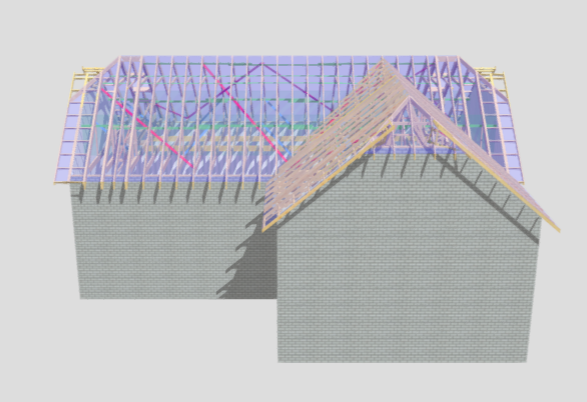

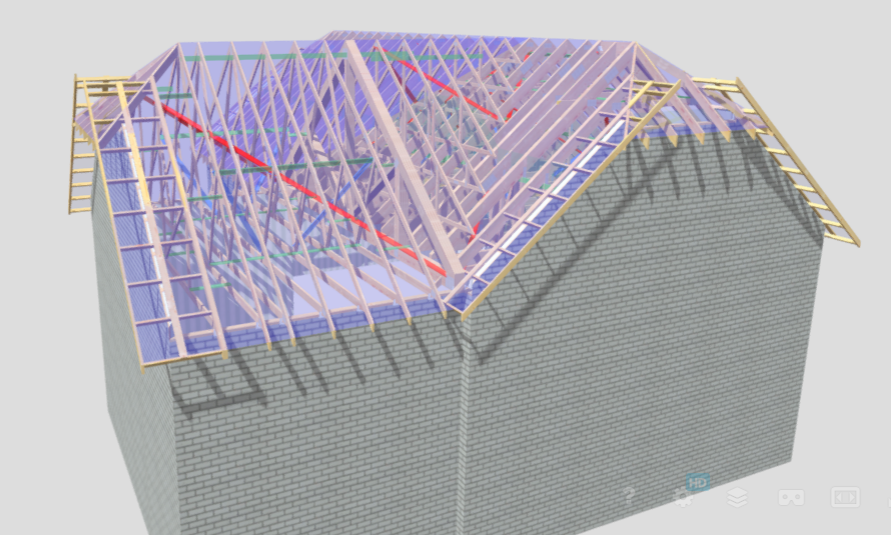

Roof structures are typically formed in an A-shape but can be produced in various styles and shapes depending on the architect’s vision and drawings.

We produce standard fink trusses, attic trusses, raised tie trusses, and scissor trusses.

Manufacturing roof trusses sustainably and with precision

In 2020, we purchased our first truss press and began producing roof trusses for our clients. Our trusses are made from multiple straight members joined in a triangle to form the roof structure.

The truss press uses a ‘C’ hydraulic clamp mounted on an A-frame. It puts pressure on the nail plates, which are used to fix the individual members together and secure them in place to form the shape.

Our truss press boasts a start/stop function to reduce electrical running costs, which helps us be as sustainable as possible and reduce our carbon footprint. The jig set-up embraces safe working systems, which encourages a high level of health and safety compliance within the factory.

“The service from yourselves was excellent. It makes a pleasant change to use a Company where everything turns out correct! Thank you very much for the roof trusses and associated timbers, and your answers to my queries.”

“We have been building 31 high-end houses on a unique estate in Kent, and OFP have supplied all of the roof trusses for the project. Every house is different, and it has been a pleasure working with their designers to ensure we get the roofs correct. Manufacturing and delivery has been excellent, and they always manage to achieve our deadlines, some of which have been quite difficult. We would happily use OFP on our next project and would recommend them for yours.”

Roof truss project case studies

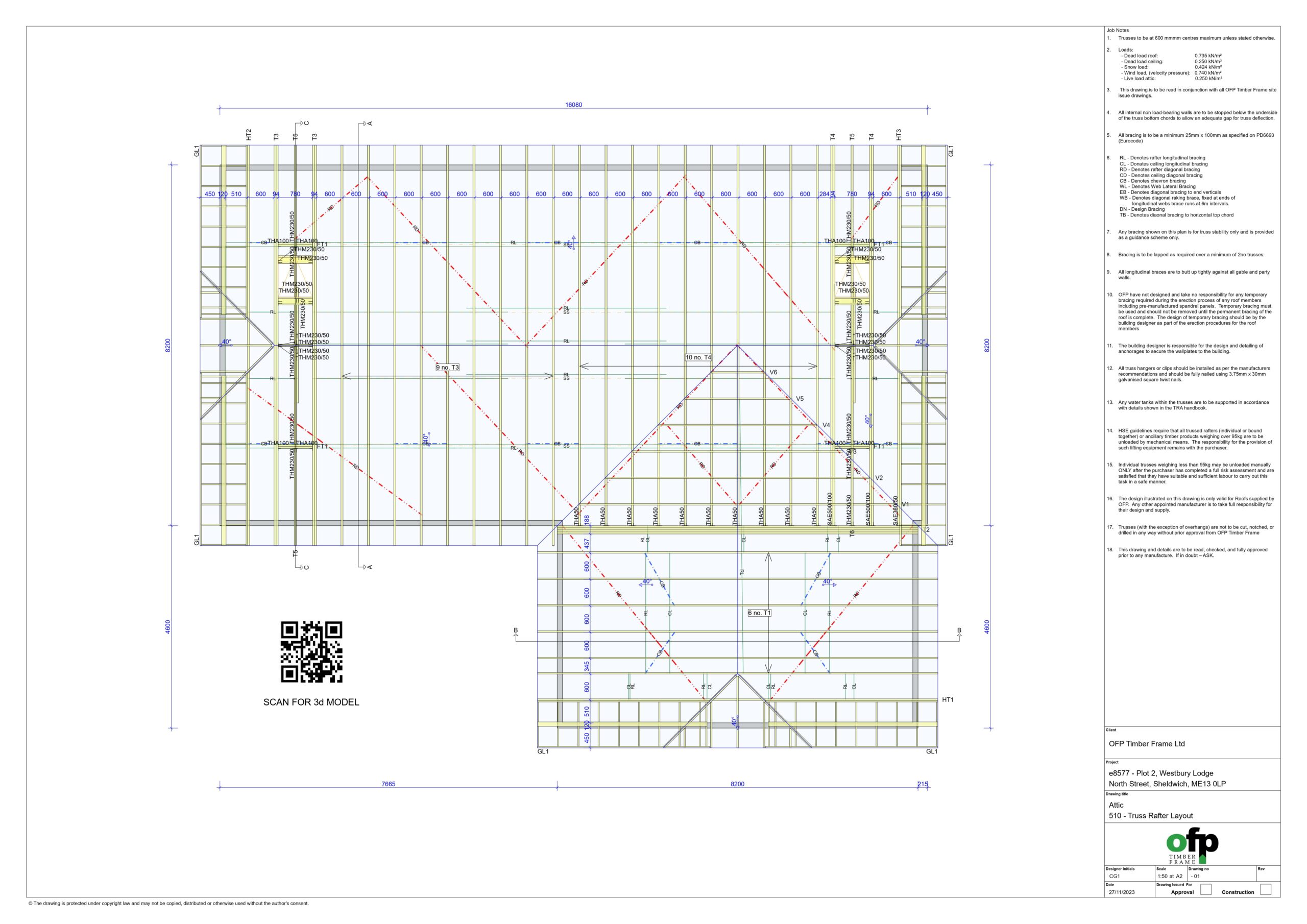

At OFP, we are flexible and versatile when producing roof trusses for our clients. We have manufactured a variety of different shapes and sizes. Check out some of our roof truss projects below:

Project: Wormley in Conningbrook, Ashford, Kent.

The project consists of 300 houses split over 6 phases. A wide variety of types were designed, including 2—and 3-storey types, terraced and detached units, and attic trusses over garages.

Learn more about Wormley in Conningbrook.

Project: Cliffe Woods in Medway, Kent.

We produced these roof trusses off-site, resulting in a speedy and precise installation when we arrived on-site.

Project: Cranleigh, Surrey.

This project in Cranleigh is comprised of 118 units and OFP was delighted to be the exclusive timber frame partner on this site and various others.

Learn more about this project in Cranleigh, Surrey.

Other OFP roof truss installations across south-east England

Conclusion:

OFP is committed to providing a complete timber frame solution from the ground up. Timber frames are incredibly versatile, flexible and accurate, making them the perfect solution for any structural design and architectural vision.

If you have an upcoming project, why not consider timber frame?

Get in touch with us to discuss your next project or arrange a factory visit to see our manufacturing in action.

Contact

T: 01304 613298