There is nothing more rewarding or exciting than helping to bring a project to life that is truly remarkable in the nature of its design and sustainability credentials.

More and more architects are opting for Modern Methods of Construction (MMC), such as timber frame, for their upcoming projects because of the benefits it offers.

At OFP, we have extensive experience of working closely with architects from the initial creative idea through to the project delivery.

Here we take a closer look into a ongoing timber frame project, Pippin Barn, that we absolutely love working on with Hawkes Architecture and the process of how we help architects bring interesting and performance-driven buildings to life.

A closer look: Pippin Barns

The brief:

Hawkes Architect initially contacted us in March 2022, and we were so excited to work on such a unique local project. We issued a proposal based on the architectural planning drawings and 3D models. We knew it would require an all-encompassing team effort with exceptional and inventive thinking, and we were excited by the challenge.

Having discussed the project with the design team right from the start and working closely with the client, the client’s engineer and the architect throughout to generate a structural specification, we identified tricky elements on the 3D model and proposals. This included compound angles on roofs and soffit lines, large amounts of glazing, overhangs, cranked steels, cladding details (including mathematical tiles) and balustrades.

The solution:

From these discussions, we were able to identify key solutions to make the project a reality in a cost-effective and buildable way.

Throughout the design process, the input from OFP’s technical team allowed the architect to update their drawings in conjunction with the engineering regularly. This led to the development of the drawing and engineering pack, which was eventually finalised.

In terms of materials, we discussed various products and insulations depending on availability, efficiency, and, ultimately, green credentials. It was always the top criterion that the building fabric was built environmentally and for long-term sustainability ‘in use’ when occupied. The project used high-specification glazing and Warmcel Insulation, which is sustainably manufactured from recycled newspapers. The south-facing orientation of the build maximises solar gain. All that, coupled with the natural benefits of timber frame construction make for a wonderful project in construction and beyond.

The result is a stunning, unique piece of architecture that we can all be proud of.

Supporting architects to create interesting and performance-driven buildings through timber frame

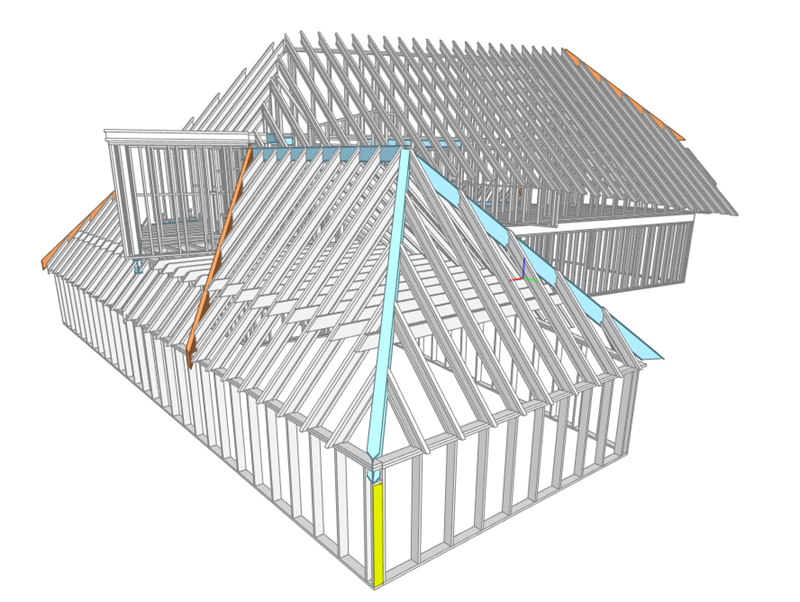

3D Design – We receive 3D drawings from architects and create preliminary timber frame 3D drawings. From there, we can create full 3D timber frame drawings, which help bring the architect’s design to life. Having a full 3D design before commencing the build onsite allows us to predict any potential issues and resolve them beforehand.

Performance – Timber frame buildings have excellent thermal insulation, resulting in an energy-efficient building. Timber frame buildings far exceed those built using traditional materials regarding thermal efficiency and go way beyond Building Regulation requirements.

Creativity – Timber frame is a versatile and flexible building material that meets most structural and visual requirements. From large housing developments to unique design-led buildings, timber frame provides the capability and versatility to achieve any structure. This allows architects to be creative and innovative with their future designs.

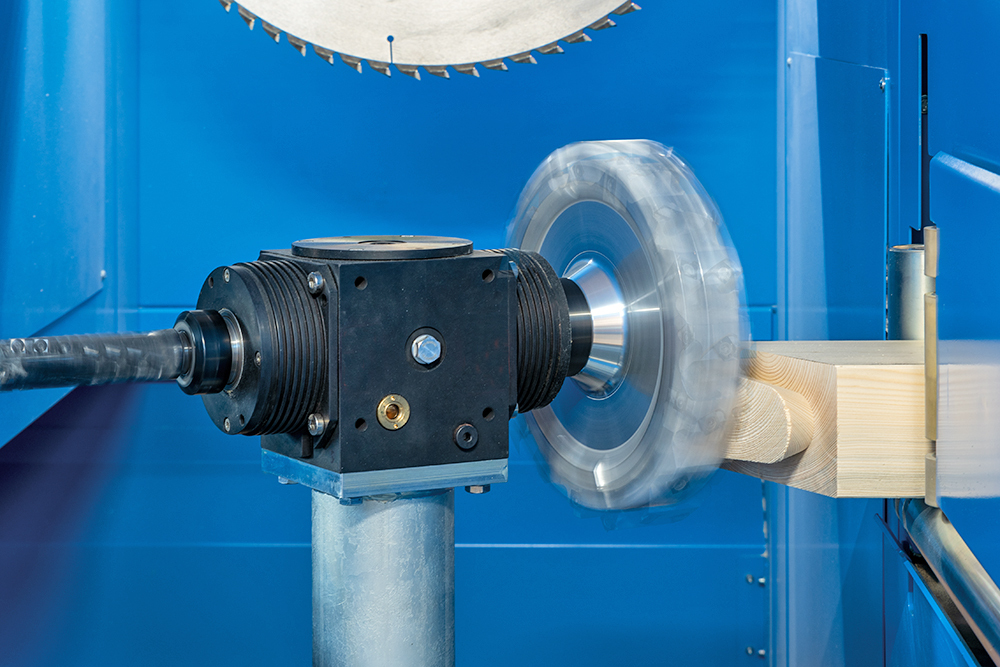

Technology – A complex project requires state-of-the-art technology. We utilised our hundegger automated saw. This technology allows us to create intricate and complex cuts based directly on the CAD model. This allows for precision like no other.

For the Pippin Barm project, the timber frame elements were drawn and detailed in the software Dietrich’s, this produced files direct to our Hundegger saw allowing us to fully utilise its capabilities. With the purchase of our new Turret Mill, the Hundegger was able to notch the timbers allowing the members to be slotted and fixed together on site to the precision of the model.

Sustainability – As the government continues to emphasise the importance of MMC and to achieve environmental targets, we must invest in the right sustainable building solutions.

Not only is timber sustainable in its production but once it reaches the end of its lifespan as a building material, it can then be transformed into energy as biomass or redistributed as chipping for agriculture, for example.

Are you an architect with an upcoming project? You are invited to come and visit us in our factory, and we will take you through how we can work with you to bring your design to life.

Contact us directly, and we will be happy to discuss your next project with you.

T: 01304 613298 E: info@ofptimberframe.com